Omenetto’s work leans on the Utopian side of the scale, which is why he was awarded the foundation’s Eliasson Global Leadership Prize in 2017. An interdisciplinary research facility that investigates materials at the interface between technology and life sciences, Silklab’s goal is to create innovations and find solutions using naturally derived, abundant, sustainable materials. Like silk. The fiber produced by silkworms to make their cocoons is a protein, as Omenetto explains it, and by reverse-engineering the silk thread and extracting the protein the thread’s made ofn, “you can reshape it into basically whatever you want.”

Silk is flexible, resistant, and can be made electrically conducive when combined with silicon, magnesium, or gold. “It’s biocompatible and safely implantable in the human body, capable of absorbing and releasing substances over time and biodegradable in a programmable way,” says the pioneering scientist.

Over the past decade, Silklab has established itself as one of the world’s premier laboratories for advanced biomaterials technology. It has pioneered applications in edible and implantable electronics, food preservation, energy harvesting, wearable sensors, compostable technology, distributed environmental sensing, medical devices and therapeutics, biospecimen stabilization, advanced medical diagnostics, and structural components.

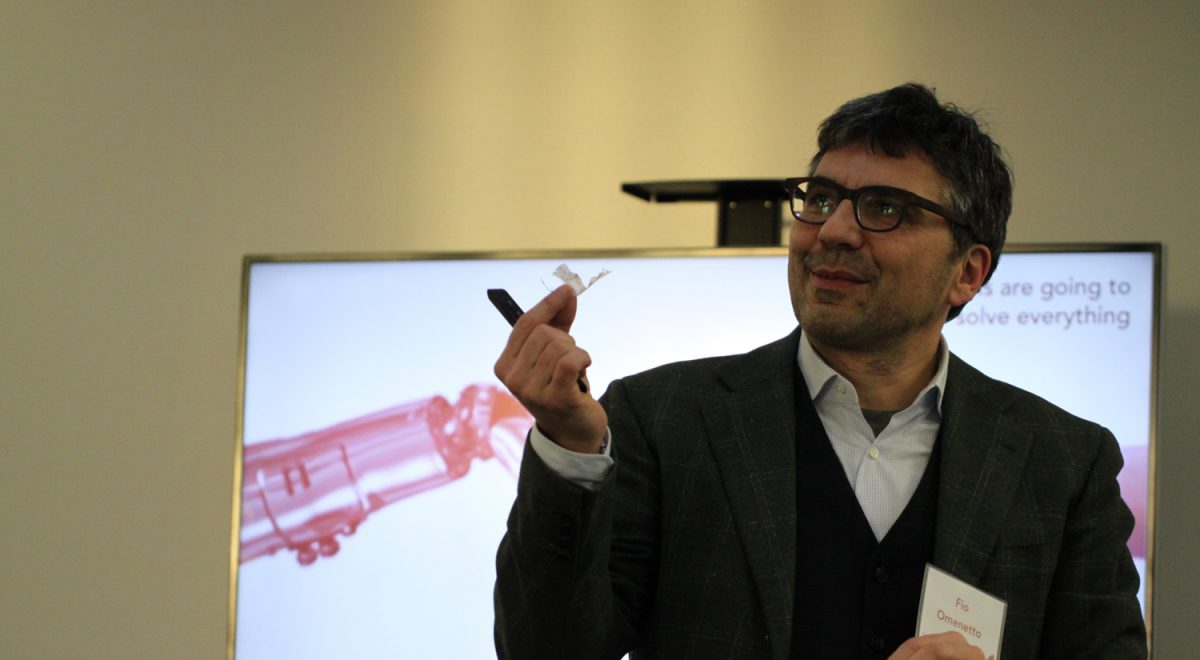

Tällberg asked Omenetto about the genesis of his work, and where he’d like to take it.

How did you discover the potential of silk as a building block for new materials?

By chance, in conversation with a colleague, a silk pioneer himself and one of my closest collaborators, in the hallway. What was particularly striking to us were the optical/technological properties of the silk protein, which were comparable to the most sophisticated photonic components that technology could build. This gave us the ability to make devices where biological and technological functions coexist—for instance, a transistor made of blood. Because of the biocompatibility of the material, new formats of electronics and photonics have opened exciting avenues for medicine, manufacturing, and sustainability.

Can you give a couple of examples of innovative applications?

Silk-magnesium-based electronic devices to mitigate infection can be implanted in the body, activated wirelessly with a phone, and, after their function is done, disappear harmlessly. Edible silk coatings for food can preserve it at room temperature. Similarly, silk film can allow us to transport blood or biofluid samples without refrigeration, while maintaining the sample’s biological function and information.

How do you collaborate with other labs and other professionals?

Our research naturally spans across multiple disciplines, so we consistently engage people who are smarter than us. Often other labs or professionals reach out to explore biomaterials-based solutions for different applications. The laboratory hosts people from nearly every scientific discipline, alongside architects, artists, and public policy experts who are driven by reinventing materials to provide meaningful and impactful solutions.

What’s your dream problem that you could address in this lab?

I believe that naturally derived materials—such as silk, cellulose, or keratin—can help us reinvent manufacturing. My dream is to be able to “grow technology” and change the way we manufacture today, adding function without sacrificing performance. Solving this problem has important ramifications in global health, resource management, sustainability, and in managing climate change.

While industrialization and increasing demand is taxing our planet, material science can identify new solutions that satisfy demand while lowering emissions and depletion of natural resources. For example, these new materials can reduce food waste, enable low-cost medical diagnostics, substitute for plastics, or help reflect sunlight to protect our planet.

0 Comments